Safe testing

Safety through recognised testing method

A good quality safe has undergone a test carried out by respected and independent institutions to prove its resistance to burglary.

A good quality safe has undergone a test carried out by respected and independent institutions to prove its resistance to burglary. Tests of safes are carried out by special institutes operating in many European countries. The legal basis is the agreed European standard.

All mechanical, electrical and thermal tools with which intruders may attempt to open the safe are used in the tests:

- sledgehammer,

- angle grinder,

- drill,

- cutting torch,

- specialised tools*

* some of the tools or devices used are kept secret to prevent them being copied and used by criminals.

Reliable testing ensures safety

The safe's test result is calculated on the basis of the burglary tools used and the time required to access the contents. The burglary resistance of a safe is given in a unit called the "Resistance Unit", or RU for short. One RU literally means 1 minute of the test procedure. The safe will have as many RUs as the number of minutes it can withstand the test procedure. The resistance of the safe is calculated using a formula which is then documented on a VdS label on the inside of the safe.

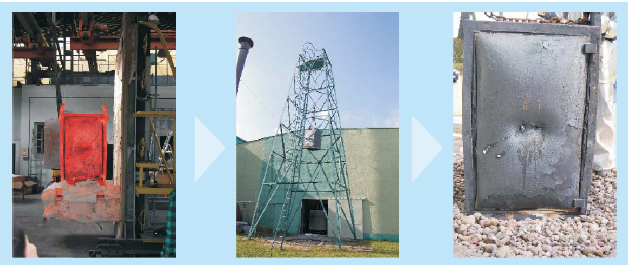

Tests of the fire resistance of a safe are carried out in accordance with control procedures relating to resistance to high temperatures.

The best known and most difficult fire test is the so-called Brunswick test, which is carried out by the Building Materials Testing Institute of the Technical University of Brunswick. This test consists of several parts.

The safe is heated at 1090 °C for one or two hours

The temperature inside the safe can only be raised by a certain worth during this process.

The safe removed from the oven is dropped from a height of 9,15 m onto a gravel or crushed stone floor.

This simulates the safe falling from the 3rd (third) floor of a burning building.

The safe is again heated to 840 °C and then cooled down.

The entire duration of the test is approximately 24 hours.